Brake controller

The software in the brake controller calculates the required brake performance on the basis of 3 components. As a result, we have the right brake performance in every situation, loaded or not.

- G-sensor: This registers the deceleration of the towing vehicle.

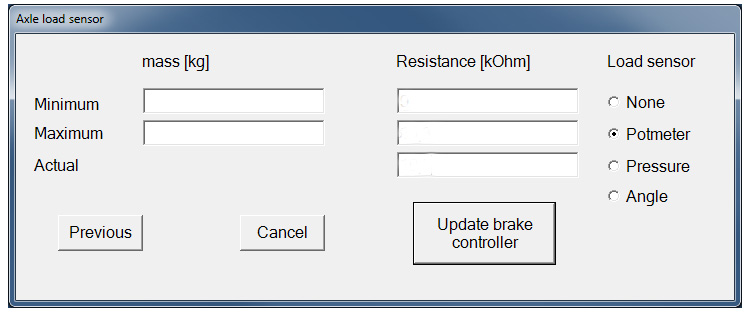

- Axle load sensor: The sensor measure current axle load of the trailer, so you have the right brake performance loaded or not.

- programmable parameters:

Leds brake controller.

- Level:led lights up green when the controller is levelled. This is important because the G-sensor not only measures the speed decreases, as well as angles of inclination. The advantage is that more brake performance is supplied automatically downhill and that given the additional gravitational acceleration that the vehicle is experiencing desirable.

- Brake active: This led lights up red if there is a brake signal from the car.

- Battery low: This led lights up red when the voltage of the battery on the trailer has become too low. The controller activate the buzzer in the car. This gives an audible alarm signal.

- Error:This led lights up orange as one of the axle load sensors has no signal.

Programming brake controller.

For more information on programming the brake controller see:

Programming brake controller.